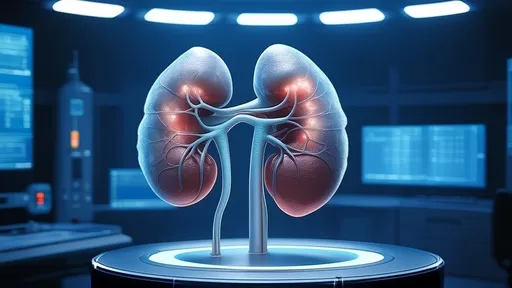

The field of regenerative medicine has taken a monumental leap forward as researchers announce the successful completion of animal trials for a 3D-printed artificial kidney. This groundbreaking development could potentially solve the chronic shortage of donor organs that has plagued transplant medicine for decades.

After years of painstaking research, a multidisciplinary team from several leading institutions has demonstrated that their bioengineered kidney can perform essential functions when implanted into test animals. The artificial organ, created through an advanced 3D bioprinting process, marks the most sophisticated attempt yet to create a functional replacement for this vital organ.

The implications of this success are staggering. With over 100,000 patients in the United States alone waiting for kidney transplants, and thousands dying each year before receiving one, this technology could revolutionize treatment for end-stage renal disease. The research team cautions that human trials are still several years away, but the animal trial results provide compelling evidence that the approach is viable.

What sets this artificial kidney apart from previous attempts is its complex vascular structure and cellular composition. Unlike earlier prototypes that focused solely on filtration, this version incorporates living renal cells arranged in precise geometries that mimic natural kidney tissue. The organ was printed using a special bioink containing these cells along with supportive scaffolding materials that gradually dissolve as the engineered tissue matures.

The animal trials, conducted over eighteen months with porcine subjects, showed promising results. The implanted kidneys began producing urine within weeks and demonstrated the ability to regulate electrolytes and filter waste products from the bloodstream. While not yet matching the full capacity of natural kidneys, the organs performed at approximately 60-70% of normal function - more than sufficient to keep a patient off dialysis.

Dr. Helen Cho, the lead researcher on the project, explained the significance of these findings during a recent press conference. "We're not just creating a structural replica of a kidney - we're engineering living tissue that can grow and adapt within the body. The animals in our study showed no signs of rejection because we're using cells derived from their own genetic material."

The bioprinting process begins with a detailed scan of the recipient's existing kidney (or a standard model if the original is nonfunctional). Using this blueprint, specialized 3D printers deposit layer upon layer of bioink containing renal progenitor cells in precise patterns that recreate the organ's intricate architecture. The entire printing process for a human-scale kidney currently takes about twelve hours, though researchers expect to reduce this significantly as the technology improves.

One of the most challenging aspects has been recreating the kidney's complex network of blood vessels and nephrons - the microscopic filtering units. Previous attempts often failed because the printed organs couldn't establish adequate blood flow. The current breakthrough came from developing a sacrificial ink technique, where temporary support structures are printed and later dissolved to leave behind patent vascular channels.

Ethical considerations surrounding 3D-printed organs are surprisingly less contentious than other areas of biotechnology. Because the process uses a patient's own cells (or carefully vetted donor cells) rather than embryonic stem cells, it avoids many of the controversies that have surrounded some other regenerative medicine approaches. However, researchers acknowledge that as the technology progresses, new ethical questions about accessibility and enhancement may emerge.

The economic implications could be equally transformative. Dialysis treatment costs the U.S. healthcare system nearly $90 billion annually, with average costs exceeding $75,000 per patient per year. A one-time transplant with a bioengineered kidney, even at several hundred thousand dollars, would represent significant savings over a lifetime of dialysis while dramatically improving quality of life.

Scaling up production remains a significant hurdle. Currently, each kidney requires custom printing in specialized facilities with highly trained personnel. The research team is working with several biotech companies to automate parts of the process and establish quality control standards that would allow broader distribution. Their goal is to eventually make the procedure as routine as other complex surgeries.

Regulatory pathways present another challenge. The FDA has never approved an entirely lab-grown organ for human implantation, and the approval process will likely require extensive additional testing. Researchers are already in discussions with regulatory agencies about designing the necessary clinical trials, which could begin within three to five years if current progress continues.

Looking ahead, the team is focusing on three key areas: improving functional capacity to match natural kidneys, extending the lifespan of the printed organs (current versions are expected to last 5-7 years before needing replacement), and refining the cellular composition to enhance long-term stability. Parallel research is exploring whether similar techniques could be applied to other organs like the liver or pancreas.

The success of these animal trials has ignited excitement across the medical community. Nephrologists who have reviewed the data describe it as the most promising development in their field since the advent of dialysis technology in the 1940s. While cautious about raising false hope, many agree that we may be witnessing the dawn of a new era in transplant medicine.

For patients currently on waiting lists, this breakthrough offers a glimmer of hope where little existed before. The traditional donor system, reliant on tragic accidents or rare live donations, could never meet the overwhelming demand. 3D bioprinting presents a scalable solution that could ultimately make organ waiting lists a thing of the past.

As research continues, the team is already planning expanded animal trials to test longer-term functionality and refine surgical implantation techniques. They're also working on cryopreservation methods that would allow organs to be printed and stored until needed, potentially creating the first true organ banks.

The road from laboratory to clinic remains long, but for the first time, researchers can see the destination clearly. What began as theoretical speculation about the potential of 3D printing in medicine has now taken concrete form - a functioning artificial kidney that could save millions of lives. As one team member put it, "We're not just printing organs - we're printing hope."

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025